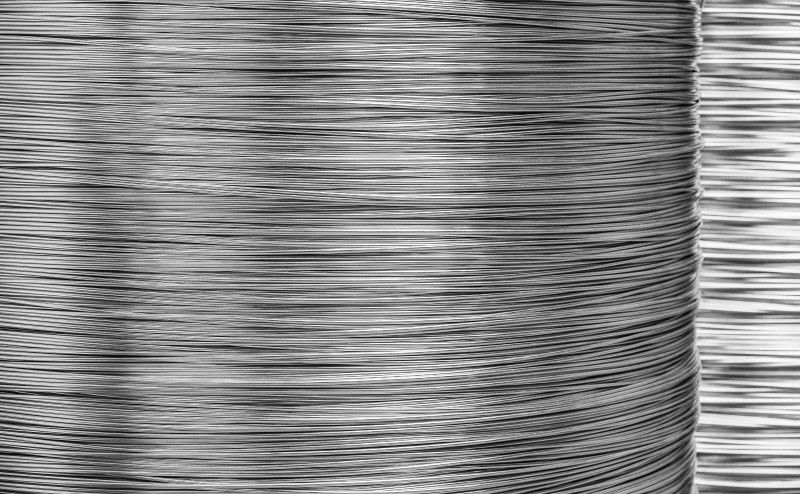

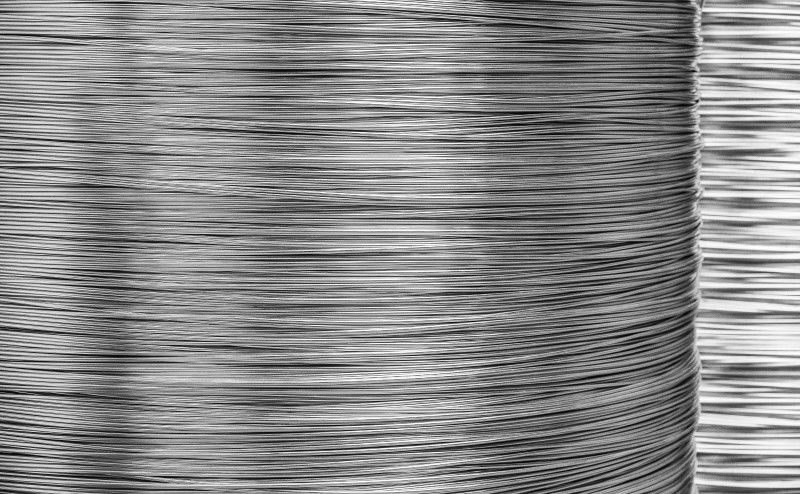

Galvanised steel wire on coil.

Hot-dipped galvanized wire, also known as HDG wire, is a type of wire that has been coated with a layer of zinc through a hot-dip galvanizing process. This process involves immersing the wire in a bath of molten zinc, resulting in a thicker and more durable zinc coating compared to other types of galvanized wire, such as electro-galvanized wire.

One of the main advantages of hot-dipped galvanized wire is its exceptional corrosion resistance. The thick zinc coating acts as a barrier between the wire and the environment, protecting the underlying steel or iron from rust and other forms of corrosion. This makes hot-dipped galvanized wire an ideal choice for outdoor and industrial applications, where the wire will be exposed to harsh weather conditions and corrosive elements.

Another advantage of hot-dipped galvanized wire is its strength and durability. The thick zinc coating adds extra strength to the wire, making it more resistant to bending and breaking. This makes it a great choice for applications where the wire will be subject to heavy loads or stress, such as in the construction of buildings and bridges, or in the manufacturing of products such as wire baskets and hangers.

Hot-dipped galvanized wire is also a cost-effective choice. Due to the thickness of the zinc coating, it requires less zinc to produce compared to electro-galvanized wire, making it less expensive. Additionally, the hot-dip galvanizing process is more efficient and cost-effective than electro-galvanizing, which makes it a great choice for large-scale projects.

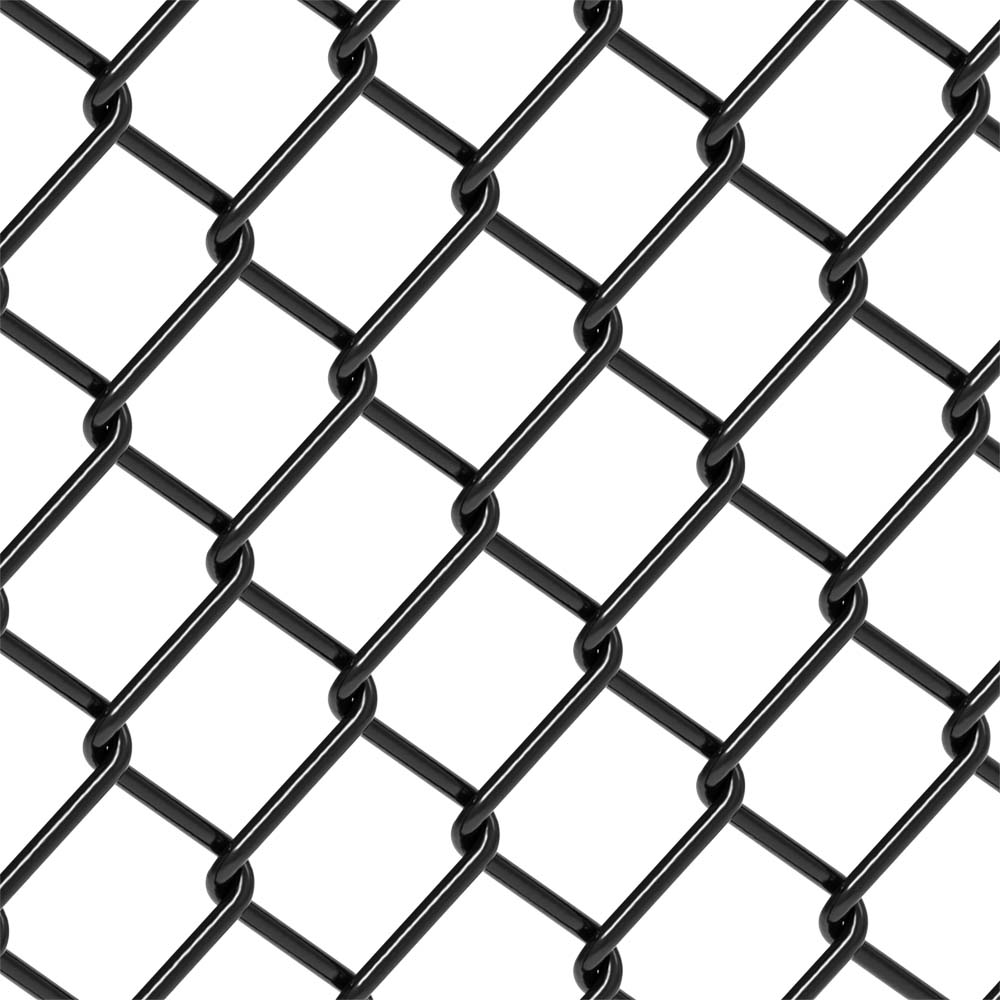

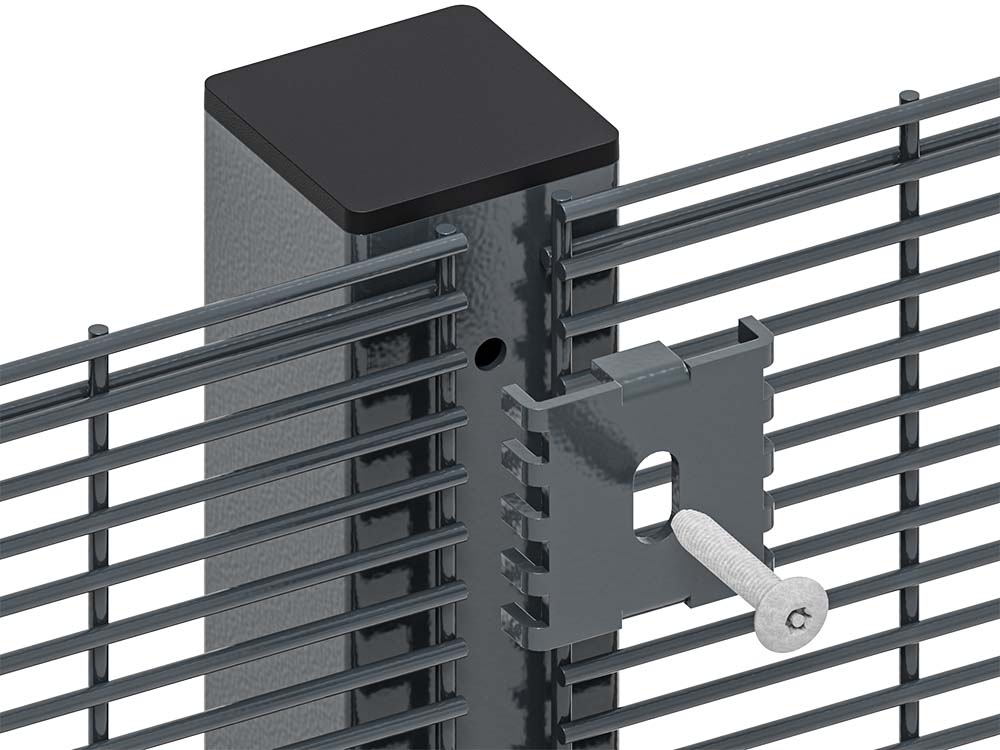

In terms of fencing, hot-dipped galvanized wire is a popular choice for the production of fence panels due to its durability and resistance to corrosion. It can be used to create a variety of different styles of fence panels, including chain link, welded wire, and woven wire. This makes it a versatile choice for any fencing project.

The hot-dip galvanizing process is also environmentally friendly as zinc is a natural element and is recyclable. The by-product generated by the process is mostly zinc oxide, which can be recycled into other zinc products. Additionally, the process does not release any harmful toxins into the environment.

In conclusion, hot-dipped galvanized wire is an excellent choice for a wide range of applications due to its exceptional corrosion resistance, strength, and durability. Its thick zinc coating provides an added layer of protection, ensuring that the wire will last for many years. Its cost-effectiveness and eco-friendly properties make it an even more attractive option. Whether you're working on a construction project, manufacturing products, or installing a fence, hot-dipped galvanized wire is a reliable and cost-effective choice.